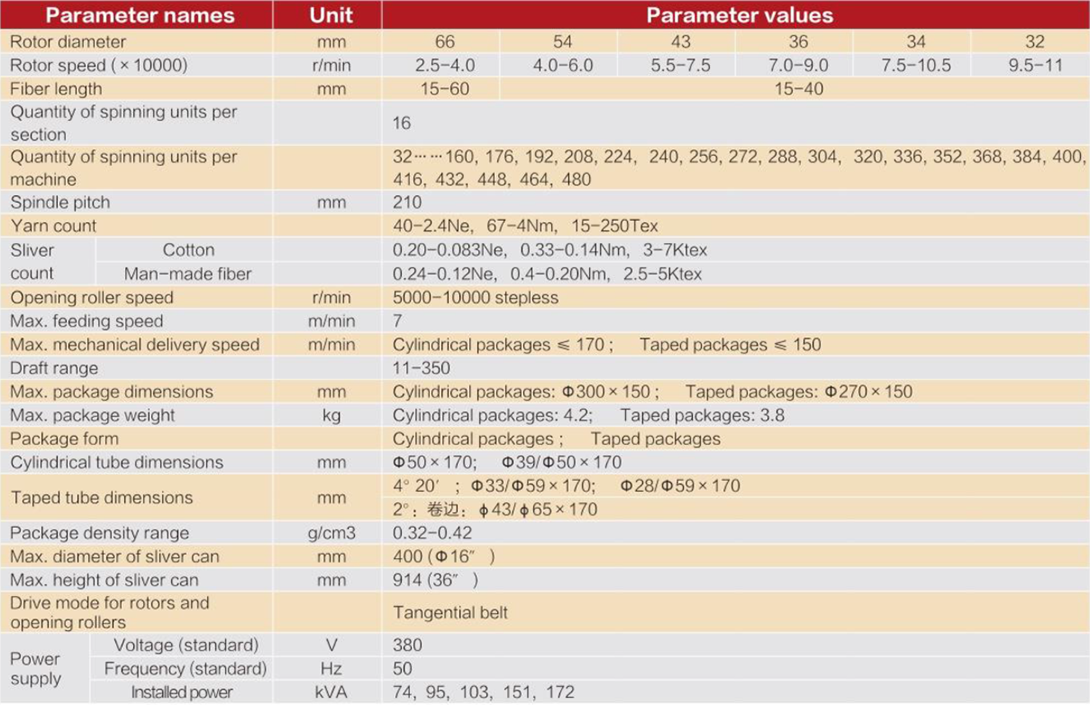

TQF- -568 rotor spinning machine is a kind of new-type open end spinning machine with some features such as high speed, high efficiency, automatic exhausting impurities. It can spin directly various short fibers, 40mm cut fibers or 60mm cut viscose into single fine yarn from combed sliver.

This is a double - side -type spinning machine based on modularized design. It applies many new technologies such as air suction spinbox, semi-automatic piecing-in, closed loop control etc. Max. rotor speed can reach 110000rpm.

Thanks to application of numerous new technologies, it holds spinning and winding quality close to full automatic rotor spinning machine, and then shows better price- performance ratio.

0575-86288859

Zhejiang Taitan Co. Ltd

Zhejiang Taitan Co. Ltd  Email

Email

浙公網(wǎng)安備 33062402000018號